Homebrewing Recipe | Free From Amber Ale

The number one thing you will learn as a brewer is that there is always room to improve. Even the most professional people in the business know this. The very first beer I ever brewed was an amber ale that somehow surpassed all expectation by getting infected and tasting like sour lemons. There’s no shame in admitting it because everyone has gone through a similar, baffling situation in their first year of brewing.

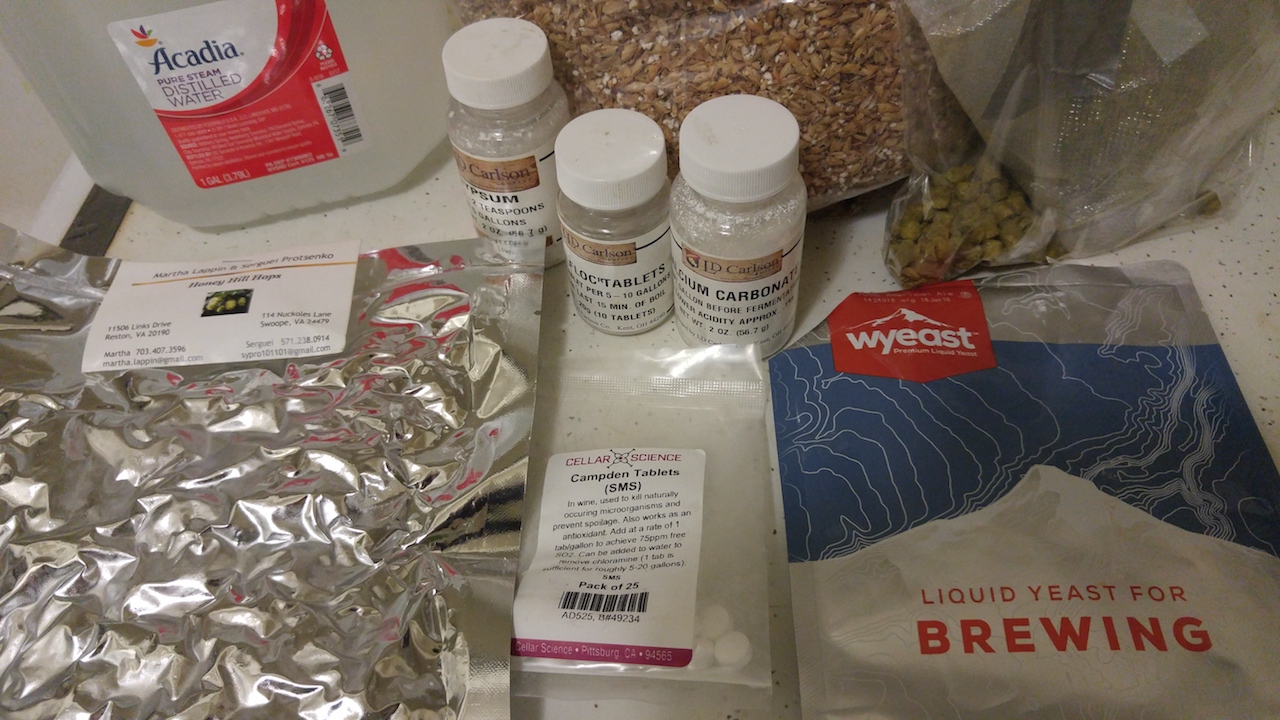

Thanks to criticism from professional judges, I’ve found out what has been the bane of my brewing existence since I moved to a new apartment. Three of my beers were found to have medicinal off-flavors, resulting in band-aid/astringent tasting bottles. This type of problem can occur due to over-crushing grains or yeast contamination, but I was convinced it was a problem with the water. These reasons are why I constantly advise brewers to learn about the chemicals in your water source (using a system like Ward Lab) or by talking out the issue with other local homebrewers. Using the Brewer’s Friend Water Chemistry Calculator is a good way to figure out what needs to be added to accommodate your beer recipe.

The solution I found came through using Campden tablets. This brewing additive is normally used for sterilizing wine or cider, but can also be useful for removing chloramines in your tap water that produce these off-flavors. Now this doesn’t apply to everyone, but my homebrewing friends suggested it would be a good way to eliminate one source of the problem. The batch in which I tested this theory (with great success) is the one I’m delivering to you now: Free From Amber Ale.

From the very first step, I had to change up my brewing process. I added a third of a Campden tablet (one whole tablet is used for 20 gallons) during my strike water stage along with my other traditional brewing salts. My tap water is too alkaline, which is why it requires calcium chloride and gypsum to lower the PH. You technically can boil your strike water for 15 minutes to remove the chloramines, but boiling that much water can eat away a lot of time/gas for an already time-consuming hobby.

The Recipe

- 7 lbs of Pale Malt

- 2 lbs of Munich II Malt

- 1 lb of Carastan Malt (Replace with Crystal 40 if necessary)

- 8 oz of Crystal 120L Malt

- ½ oz of Nugget Hops

- 2 oz of Leaf Cascade Hops (Substitute for 1 Oz Pellets)

- 1 Whirfloc Tablet

- 1 Package of Wyeast #1056 – American Ale (Requires a Starter Made the Day Before)

- 1/3rd Campden Tablet

- 5 grams of Gypsum

- 5 grams of Calcium Chloride

- Filtered Tap Water

- 2 Gallons of Distilled Water

Boil your strike water to 158 degrees Fahrenheit. Add in your brewing salts (gypsum, calcium chloride and Campden tablet) first to dissolve. Once your water hits temperature for a few minutes, line your kettle with your mesh straining bag. Slowly mix in two pounds of grain at a time before gently mixing with a paddle or long spoon so the wort does not clump together. Once you have added all of your grains to the kettle, make sure your mash temperature stays between 148-152 degrees Fahrenheit for an hour.

In a separate vessel, prepare two gallons of distilled water by heating it to 175 degrees Fahrenheit. This is for the sparging step: We will extract as much as we can from the grains after their mash.

After the mashing step, carefully remove your grain bag from the brew kettle and empty it into a sanitized container. Pour your heated, distilled water over the grains to sit for about 10 minutes. At this stage, I use a sanitized scoop and strainer to place the solids in a trash container and add the liquid back to the boil kettle. Set your heat source to high and prepare the rest of your materials until the wort hits a roiling boil.

Once the wort hits the boil, add in 1/2 oz of Nugget Hops. I love using Nugget for its bitter versatility in many different beer styles. An Amber Ale is not a hoppy style, but it does require hops that match the profile. The light woody, earthy character holds up against the selection of sweet, caramel grains quite well. I boiled the hops for 60 minutes without much deviation, only adding my whirfloc tablet and wort chiller 15 minutes before the boil ended. Since my beers were getting marks for having an underwhelming hop presence, I wanted to beef up the hop aroma by adding Cascade during the whirlpool (cool down) step.

Free From Amber Ale was fun to make not only in order to learn my new water chemistry, but it also marked the first time I used leaf hops. These hops were grown by local Honey Hill Hops, freeze-dried from last year’s harvest. Leaf hops provide a fresher flavor and aroma and easier clean up but require much more volume to get that necessary bitterness. When I used what I thought was 2 oz of dried Cascade, it expanded to about 8 ounces total! I had to adjust my beer recipe for the changes but since this was done in the whirlpool for last-minute hop presence, it wasn’t much of a change.

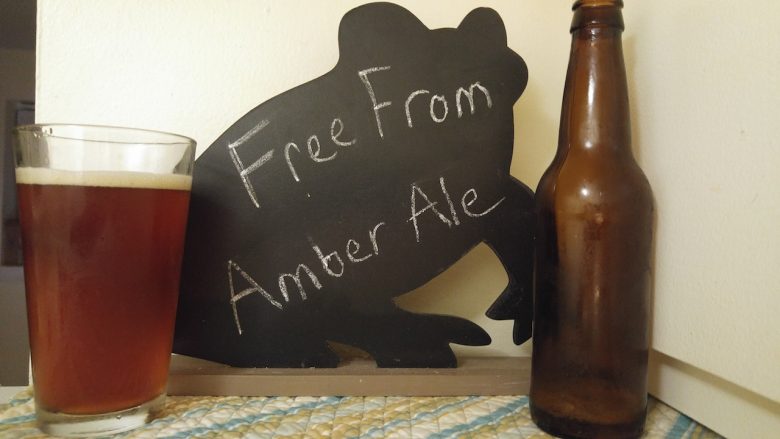

So what were the results of two weeks of fermenting and two weeks of bottle conditioning?

Free From Amber Ale is delightfully definitive to the style. A spritz of floral, herbal hops ignites the senses, easing you to a warm aroma of toasty, biscuity malts. The strong caramel tones come alive the longer the beer breathes. Upon the first sip, that iconic crispness of the style comes through followed by a smooth mouthfeel. This amber is easy to put down, yet there are lovely toffee and black tea notes to dance on the tongue.

I saw this beer as a major milestone as a homebrewer since my first batch came as a pre-arranged kit packaged with my original, extract brew kettle. Brewing a traditional, smooth amber felt like a major step forward as a home brewer after my years of trial and error. Any recipe that I would happily brew again is a big success and I hope you add it to your personal recipe Rolodex as well. Happy Brewing!

Submit a Comment