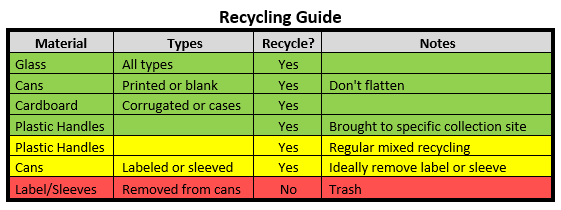

Craft Beer Recycling Guide

It’s no secret that getting fresh, tasty brews to craft beer lovers takes a lot of packaging and there are various opinions on what is and isn’t recyclable. Our craft beer recycling guide takes the guesswork out of the process so that we can all make our empties more useful.

Glass

This one’s easy. Glass is always a yes to recycle—all colors, sizes, shapes and even broken bottles. Glass can be endlessly melted and reused. Today’s bottle will live for decades if recycled.

Cardboard

Recyclers love corrugated trays and boxes and it’s fine if a label or tape remains. Can cases are a little less beloved because of a moisture-resistant plastic coating but should still be recycled.

Plastic

Plastic six- or four-pack holders—known in the trade as handles—should also be recycled, and drinkers can make a difference in the success rate.

Your best option is returning handles to a dedicated collection point. Many breweries accept empty handles and reuse them on fresh batches of cans. Likewise, PakTech, one of the largest handle manufacturers, has collection boxes some places. Its website has a map, though depending on your hometown, options may be limited.

Handles can also go in mixed recycling bins, though with a potentially lower success rate. Because of their shape, handles sometimes get incorrectly sorted with other flat things like cardboard and paper. Commercial recyclers do their best to keep them separate so it’s still worth dropping them in the bin.

Cans

Cans are the trickiest due to various labeling options, but also represent the most in-demand recycled material. This is where drinkers can really help out recyclers.

Blank or printed cans, where the design is applied directly onto the aluminum, are easiest. Put them straight into the bin. These are most common on flagship beers from larger breweries.

Labeled and sleeved or wrapped cans are more problematic for recyclers because almost the entire can is covered with plastic. Automated sorters frequently identify the cans as plastic and send them into the plastic pile. Even if they stay with the aluminum, they reduce the quality of the product.

Recyclers do their best to keep things separate but drinkers can make a huge impact. Simply peeling labels or removing sleeves turns them into ideally recyclable blank cans. Labels are usually obvious but sleeves can be tricky to identify. They are essentially can-shaped plastic that’s shrink-wrapped on. They are smooth and shiny and have a seam around the bottom and top edges of the can. Labels and sleeves go in the trash.

Clearly, removing labels is a lot more realistic for a couple of porch beers than after a raging summer barbeque. However, according to Marti Matsch, deputy director of Eco-Cycle in Boulder, Colorado, even if you can’t remove all the labels, it’s still worth recycling. There’s a decent chance the cans will end up being reused and keep new brews fresh for years to come.

Finally, the bonus question: to flatten or not to flatten? According to Matsch, best not to flatten. Why? Because similar to plastic handles, flattened cans get identified as flat things and routed off to cardboard-land. “It is really tricky when things are flat,” says Match. Crushing cans in your hand is OK because they still identify as three-dimensional objects.

Inquire Locally

For a variety of reasons, including technology and market demand, different recyclers have different rules on what they accept. While it may seem confusing that something is recyclable in Denver but not Dallas, the answer is simple: the financial bottom line.

Matsch explains that processing and transportation costs need to be lower than the selling price. “Here in Colorado we love glass,” because of the built-in glass market at the nearby CoorsTek ceramics manufacturer. However in some parts of the country it’s just not cost-effective to transport glass to a buyer, so glass recycling is not offered to residents.

The recommendations in this article will work for the majority of mixed-stream recycling, especially in larger cities with established programs. However it always pays to check with your local recycler or trash service.

Breweries Looking for Solutions

Given the relatively clear guidance on recyclability, craft breweries are doing their best to help. Unequivocally, every brewery I spoke to wants to use printed cans. However, as with many good works, the reality of economics and logistics complicates the matter.

In 2022 Ball Corp, one of the primary can-makers, increased the minimum order from 200,000 to 1 million cans per brand. That’s five truckloads. To put it in context, a brewery canning 200 cases a month would need around 17 years to use all those cans. Between up-front cost, storage and lack of rebranding flexibility, few small breweries can justify printed cans.

Cost and Flexibility Drives Labeled Cans

Anderson Valley Brewing Company in Boonville, California, offers a snapshot of the challenges facing craft breweries. In 2022 the brewery completed the switch from glass to aluminum in a bid to dramatically reduce its transportation footprint. It had initially ordered printed cans for higher-volume brews with year-round demand. However Ball’s minimum order increase pushed the brewery toward more labeling.

While labeled cans are more expensive per can, they offer much-needed financial and logistical flexibility. Says Kevin McGee, Anderson Valley’s president and CEO: “Right now flexibility and the ability to stay nimble is our priority. It’s all about scale.”

Copper Kettle Brewing in Denver has come to a similar can-clusion. The brewery switched off bottles more than five years ago and has experimented with various can designs. Even before Ball’s minimum order change, the brewery concluded that printed cans took up too much space, took too long to use up and required months-long lead times. Sleeved cans were simply too expensive. For its distribution footprint the brewery has found that the only viable solution is labels.

A Digital Future

Copper Kettle owner Jeremy Gobien and head brewer Greg Moore haven’t given up, though. They’re currently exploring digitally printed cans, which can be done in small quantities of a pallet or less. “If we can get a halfway decent price on a printed can I can tell you we’ll end up switching to it,” says Moore. If it works out, he’ll package the brewery’s flagship and seasonal beers in printed cans. However, the brewery will keep labeling one-off and small batch brews.

Anderson Valley’s McGee agrees the future lies with digitally-printed cans. He’s eagerly awaiting the day when advancing technology makes it feasible to make the switch. Currently, digital printing still costs about twice as much as labeling for the brewery. McGee believes some day it may even be realistic for breweries to invest in digital printing technology on their canning lines.

For Dry Dock Brewing near Denver, the day for digital printing has already arrived. The brewery recently announced a full switch to digitally-printed cans from Canworks in Austin, Texas. With its significant volume and large storage warehouse, the brewery was able to further its environmental goals in a way that also made business sense.

“After learning about the impact that wrapped cans have on not only the environment but also recycling centers, we think it’s very important to move away from them,” says co-owner Kevin DeLange. He adds: “We’re also making a serious effort to ask our customers to remove the labels from their Dry Dock crowlers, so that those cans get properly recycled.”

Peel Off Those Labels to Recycle!

For the time being, most craft brewers have to content themselves with smaller measures similar to Dry Dock’s crowler messaging. Both Anderson Valley and Copper Kettle dedicate a portion of their label to a reminder for drinkers to peel it off. Meanwhile, some brewers are using sleeves with an easy-off zipper. This carries a significant cost premium, however.

Some breweries are changing other aspects of their packaging. Ska Brewing in Durango, Colorado, recently announced the change from plastic to CanCollar paperboard-based six-pack holders. By foregoing plastic handles it expects to consume 95% less plastic. “The installation of the CanCollar Corsair is one of Ska’s ongoing, never-finished efforts to build a more sustainable future,” says co-founder and CEO Dave Thibodeau. Anderson Valley has also moved from plastic handles to cardboard.

Infinitely Recyclable

In the end, anything craft-beer drinkers can do to make sure recyclable materials successfully get into the recycling stream helps the economy and the environment. “There’s a lot of energy savings in the aggregate if people remove the labels,” says McGee.

According to Matsch, a recycled can saves 95% of the energy that would be required for a new can. Aluminum and glass never degrade and are infinitely recyclable. “If you get it in the recycling bin it can go around over and over and over again,” she says. “Recycling really works when people are paying attention and participating.”

-

While PakTech does have a program to return them to them, they still just throw them away. There are only 2 types of plastic actually recycled in the US. While your local recycling accepts many more, once they sort it, they send it to the dump with all the other trash. Some years ago, more types were “recycled”. They were sold to China, who then mostly just burned them for fuel. China updated their laws to require such plastics and imports to be cleaned, which would negate any small bit of money recyclers made off selling it to them, so they’ve stopped shipping it overseas. PakTech is in Oregon, where there are no recyclers that work with the type of plastic they use in their packaging. Would lead one to assume there’s no way they’re actually recycling it.

Comments